Just What I Needed....

.... Another Project!

I'm going to give this page a bump to the top of the list because it looks like this long-lost project is finally going to get a shot at being constructed. Last week, the "slowly worsening rod knock" in my truck turned into a horrible clattering, indicating that the bearing had failed and now the connecting rod cap was hitting the crankshaft journal. Engines in this condition don't last very much longer, so 16+ years after taking the first action to convert my pickup to diesel, I've dug everything out from under the workbench and out of the storage locker and considering how I'm going to pull it all off.

Check this space for future progress, it's time for some current content on the site, and this is as good a subject as any I've had in a long time.

-S

(This page originally posted on August 12, 2007)

Spent some time on eBay last week and made a purchase I have been watching for for a long time:

A Mitsubishi 4D56 2.5 liter turbo diesel engine, which, with parts from this:

1987 Ford Ranger turbo diesel (from the factory!), is going into this:

1987 Ford Ranger XLT 4x4 (gas powered from the factory).

I know, lots of work, engine swap, wiring changes, fuel system revisions, etc., but I am seriously over gasoline power and want a small pickup that will run on Biodiesel, and my 4x4 is in excellent shape (other than the engine, which is tired and has a slowly worsening rod knock).

The diesel Rangers are rare to begin with, but the 1987 model year is ~very~ rare. I purchased the red truck for $100 from a Country Fair associate, who had parked it due to a blown turbo and leaky head gasket. I bought it a couple of years ago, put a used wrecking yard turbo on it and drove it the rest of the summer. Whatever was wrong with the head gasket really let go that October, as the engine would overheat within a couple of miles of coming up to temperature. There always was oil in the water and water in the oil, so I knew the engine had significant problems.

Checking around, the 4D55 engine (which came in the red truck from the factory) is very difficult to get parts for, as few of them were imported into the US. Some diesel Dodge Ram 50's used them, and a couple of years of limited production in the Rangers and that's about it. In the rest of the world they are a very common power plant, and mostly have been supplanted by the 4D56, a slightly larger displacement engine of the same configuration. The two engines share common parts and are interchangeable.

This particular engine was purchased from a JDM (Japanese Domestic Market) reseller, and came out of a 4x4 vehicle with 40-60,000 miles on it. In Japan, older and high-mileage vehicles are taxed at a higher rate, and subject to more stringent inspections, so cars we would scramble to buy used over here are regularly chopped to pieces and the drive trains shipped to other markets for resale.

Some time this fall or winter, I'll tear down the red Ranger, pull the engine and partially disassemble it. The new engine has some different flanges and mounting plates, and the entire front cover of the engine has to be swapped in from the old 4D55 so that the power steering pump, alternator, and vacuum pump can be mounted. I'll also change over the oil pan to make sure all the clearances under the engine are OK.

After I get the two engines melded into one, then the real fun begins, tearing my faithful old Ford down, and swapping the electrical, fuel, power steering and cooling system components over from the red Ranger. Having a diesel donor vehicle is the only way I would attempt this kind of a swap, all of the plumbing, wiring, brackets, mounts, etc are all there and will easily unbolt from one and bolt into the other.

The Ranger was available with the diesel engine option from 1983-1987

The '83 & '84 engines were a naturally aspirated design by Perkins built by Mazda. It had 59 horsepower and 90 foot-pounds of torque.

Understandably, they were found to be woefully underpowered.

In 1985, the Mitsu 4D55 TD engine was introduced, with 72hp @ 134 ft.lbs torque. Even as tired as the red Ranger was, I considered it's performance to be about equal to the 2.3 liter gas engine in my 4x4 (90hp), but with a much more usable torque band at lower RPM's. And this was with factory specs, I didn't do any performance tuning on the old engine. Add an intercooler, larger exhaust, advance the timing a bit and increase the fueling and you'd have a very willing power plant.

The 4D56 is 2.5 liter comes in at 83hp from the factory. My research shows that it's possible to bump this up to about 130hp with some careful tuning and bolt-on modifications.

I suppose just getting it installed in the engine bay and driving the truck forward should be my first goal...

-S

Ranger Diesel Swap 2

Setting the Stage

I spent lots of "spare" time since the last update taking measurements in the engine compartments, making cardboard templates of things that stick out on the new engine and comparing them with the available space in the diesel Ranger (because I could measure them from similar points on the diesel engine that's already in it, otherwise the trucks are identical), seeing how things fit together, where the motor mounts to the frame, etc. All looking for anything that would dead-end the project, but didn't find anything.

I'll have to swap the oil pans between the old and new engines, as well as the intake manifold, both due to clearance issues. All of the accessories, alternator, vacuum pump and power steering pump will swap over as well. There may be some fabrication involved.

It's not necessary to start with, but I've been scoping out the possible location of one of the two intercoolers I have on hand. The grille area is already tight for space, I'll likely have to lose the fog lights in the grille on the new truck.

Also went back through my research from 16 years ago, dove deeper into the transmission and transfer case documentation, found a PDF shop manual for the new engine, and sorted through some of the spare parts that I bought back then to make the conversion (gaskets, mostly).

A friend visiting from Portland and I put the 8'x12' truck box I've had for a few months up on pier blocks and leveled it. This will be the disassembly and storage area for everything, so I don't clutter up my garage. Last trip over to the Big Smoke (big city), I went by Halbol Fleight* and picked up an engine stand and 20 gallon parts washer tank. I expect lots of grease, LOTS of it, from all three engines, and want to deal with it as painlessly as possible. Friend from PDX already loaned me a very capable engine hoist for the job. The truck box is outfitted with overhead lights, ample shelving, a roll-away tool cabinet that can be used as a small workbench, and there is a small assortment of tools, wrenches and sockets, etc, that might save me a trip back to the garage once in a while.

First step in this phase of the project was to make the red Ranger donor truck roll again. Last time I tried to move it, the front wheels were locked solid, and after dragging it around the yard with a 4x4 in an ineffective attempt to put it into position, I gave up and used the loader on my backhoe to pick the front end up off the ground and dollied it out of the way. This needed a remedy, as I have to be able to roll the truck into the carport where I will pull the engine out with the hoist, and there was no way I was going to be able to move it to that area with the tractor. The simple solution was to remove the front brake calipers and pull the brake pads. Full disclosure: a sledge hammer was involved, and it wasn't all that simple.

Really, things aren't going to get going until I get the old engine out of the donor truck and get the bell housing from it. Once I have that, I can install the starter on the new engine, shunt a few oil lines so it doesn't spew, and make it run. This is the necessary first step in doing the conversion. If I don't have a running replacement engine, then I don't tear down my white Ranger. If it runs, then I fab up some kind of radiator, fill it with water and run it up to temperature.

Until now, all I had for documentation of the installation of the diesel engine in the Ford Ranger was what little I could find in an old Clymer repair manual. Most of the information was vague, intended more for an owner who would be changing their own oil and such. No fuel system or wiring diagrams were presented, and I need both to do a proper installation of the diesel in my gas truck. On the off-chance that something more fully documented existed, I did a search on fleaBay* and found many instances of the OEM Ford shop repair manual for the 1987 Ranger. One listing included scans of the index pages, and it appears that diesel fuel systems and wiring diagrams are included, as well as very detailed procedures for servicing and disassembly of all parts of the truck. If tomorrow wasn't Columbus Day, I could go down the the Post Office and pick my copy up, it's been delivered, but won't fit in my P.O Box, so I get to wait until next trip to town this coming week.

This is a long term project, without a doubt. When I need a truck, I'm driving a Tundra that I borrowed. It has some issues, and I had to do a brake job on it before I could go anywhere. I put the first tank of gas in it last week, and I'm not used to that much sticker shock! There's a reason I drive the EV whenever I can...

*A FOOTNOTE: - I'm misspelling the names of these large, for-profit companies purposely because I find it amusing, but also because I don't see why I should be littering my website with their already well-known names. I do this with most every too-large institution, right down to the health care facility that provides my medical needs. Anyone want to argue about it on Facecrook? Look me up on Gooble.

Ranger Diesel Swap 3

Two weeks of fairly intensive research, figuring, measuring and imagining and now I'm better informed and still not completely sure that this engine conversion is going to work.

The original idea was to do a complete, factory-correct installation, what with having a donor truck that had all the parts necessary for such a job. Then I started thinking that this might be going too far to start out with and that a more moderate approach might be the better plan, with an eventual build-out with the original diesel wiring harness, engine control module, instruments, etc. The "new plan" was to use the Mitsubishi accessories (alternator with an attached vacuum pump, and the power steering pump), and just get the engine in the 4x4, get it running and tinker with the niceties as time permitted.

One important research discovery was a Mitsubishi Delica owner's forum, which contained a wealth of information about the 4D56 diesel engine and gave sources to purchase needed repair and maintenance parts. In trolling through a variety of topics, I discovered through looking at pictures of installed engines, that the JDM engine I bought in 2007 was definitely installed originally in a Mitsubishi L300 Delica. All of the part placements were correct, and the kicker was the duct pipe that leads from the air cleaner to the turbo inlet.

Some of the forum posts described how Delica owners dealt with niggling problems like the glow plug control circuit, fuel filters and such, and modification to the engine such as EGR (exhaust gas recirculation, an emission system) deletion. From this I formulated the idea that it would be completely possible to approach this initial installation as if it were an old 1980's VW IDI diesel engine. Being mechanically injected, the new diesel doesn't really need much more than fuel connections, an ignition wire, a starter signal, and the other common systems like radiator, exhaust, etc.

Well, careful measurement of the engine compartment and chassis of my 4x4 has proven that it's just not possible to install the alternator on the new engine in the mounting brackets provided for it without cutting the frame rails some in my 4x4. I'd be very reluctant to do this, and tried for days to find a solution, such as moving the oil filter to a remote location to free up some room for the alternator and vacuum pump. This morning, I made careful enough measurement to confirm that even this won't help enough.

In all, I came back to using the Ford alternator, vacuum pump and power steering pump, even in a ghetto installation to get the truck operational. Probably the hardest part of that is going to be the power steering pump, as there are a couple of mounting bolts that don't have a corresponding bolt boss in the new engine casting. The two that are there aren't drilled and tapped, so I have the nerve-wracking task of drilling and cutting threads in the cast iron block of the engine, with the hopes that I don't drill through anything important while doing so.

The last and final (?) thing I needed to do was to be absolutely sure that the the 4D56, which is much larger at the bottom than the gas engine I'm taking out, would actually clear the suspension under the truck. The Ranger 4x4 front suspension is much different that the two-wheel drive pickup I'm scavenging for parts. Ford uses (or used, I don't know if this is still a thing) "Twin I-Beam" suspension. On the 4x2 truck, all of this is neatly tucked inside the cross member under the engine. The 4x4, however, has a pivot bracket for the right-hand wheel beam that is mounted to the rear of the cross member, and looks like it will interfere with the crankcase pan of the diesel.

I spent some time today rolling around under both trucks with a machinist's rule, taking measurements. When I got out of bed this morning, I knew this would be a make-or-break matter for the swap. I never was able to confirm to my satisfaction that the 4x4 Ranger (or the Bronco II) were ever offered from the factory with diesel power. Since discovering the differences in suspension, the viability of this engine swap was always a big "Maybe".

My measurements came down to the one area where the pivot bracket is attached to the cross member. This just barely clears the cast aluminum pan on the gas engine. What I found on the installed diesel in the 4x2 truck was that there is a nice, flat "dent" in the pan at this area. I had thought upon seeing it some time back that it was just road damage from hitting a rock or limb or something, but now I think that the crankcase pan was actually designed and stamped at the factory to clear the suspension on a 4x4.

I've now updated my expectation of success in the project from "Maybe" to "Maybe-Probably". There's still a lot of work to do.

A couple of images of an engine that I didn't buy. A brand-new, latest version of the 4D56, complete long block engine only lacking the injection pump and accessories from my old engine. At the time, I just didn't know enough about what this swap would take or if the 4D56 was going to be a direct replacement for the 4D55 that I have in my donor truck. At $2500 each, these were a steal. I'd put that out fast for one of these today

Ranger Diesel Swap 4

Here's an update for my viewer:

It's been said that bad news travels fast, and in my case "fast" is about 16 years it seems. The JDM diesel engine that I purchased back in 2007 was purported to have 40 to 60,000 miles of use on it before it was removed from the original vehicle.

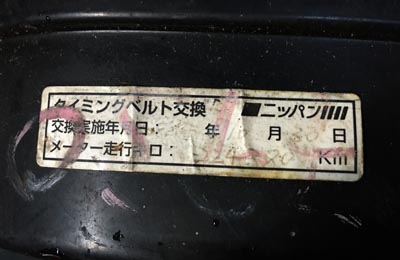

In my preparations for installing the engine a couple of weeks ago, I dug out some of the parts that I had removed when I first acquired the engine, including the timing belt cover from the front of the block. I noticed a small sticker on top of the cover, with Japanese printing on it, and took little notice of it as I don't read Kanji. Then I noticed that there were faint ballpoint pen marks on the sticker, numbers, followed by something I could understand: "Km", or Kilometers.

A quick search of the Delica forum later, I had an answer I didn't like. The sticker was notification that the timing belts(s) had been replaced at 224,320 kilometers, or about 139,000 miles.

There was also a place where the date the belts were replaced, but this was less helpful, as the year was either not filled in, or the ink had faded completely away. If the maintenance schedule had been carefully followed, this would have been the second timing belt replacement in this engine's life. Without an idea what year the belt was replaced this time, I could only speculate as to how many additional miles the engine has run with this belt. Perhaps as many as another 60,000, as belts are replaced on a 100,000 Km schedule.

Well, OK, so I have a well-broken-in engine. Being a diesel, it should have some life left in it, right? How bad could it be?? (Thinking again about the brand new 4D56 long block I could/should have bought instead)

In other news, I just picked up some additional research materials at the post office yesterday. So far, I have nothing in the way of electrical wiring diagrams or descriptions of the diesel version of the Ranger trucks. This little fleabay score will certainly help at least a little:

For the short term, the engine swap project it taking a back burner position while I put up some firewood for winter, take care of at least some of ~last~ winter's storm damage around the yard and fight the moles out in the lawn. I've also had to spend some time reconfiguring the photovoltaic panels in my solar power system due to a couple of module failures, and my hydro generator system is requiring replacement of the manifold and motorized valve that feed water to the generator. Couple this with the weather changing like a click of a switch to monsoon season and my lack of indoor workshop space, and it seems it might be a while before I make a lot of meaningful progress.

Diesel Swap (?) 5

Time for a little non-update on my non-progress putting the used engine in my worn-out truck.

Winter weather wasn't shy about coming on this year. Any hopes for an Indian Summer to finish the hot dry weather were dashed by the arrival of monsoons. The few clear days we had were punctuated by frosty, frozen nights, none of which were very conducive to wrenching outdoors.

The Toyota Tundra that I was borrowing turned out to have non-functional rear brakes, which wasn't apparent until the rains began. After a series of front-wheel lockups, and nearly leaving a mountain logging road by taking the hard way down, I returned the truck to the owner, and thanked him very much, but no thanks, I'll take my chances on leaving this plane some other way.

His response was to loan me his wife's previous car, which had just been detailed and was for sale, a 2010 Lexus LX570. 383 Horsepower, all-wheel drive, leather everything, power accessories out the tailpipe, 18 MPG. It drives like a dream, but it's like piloting a house through crowded supermarket aisles.

I named it the S.S. Lextanic.

The first trip over to the Valley for a medical appointment, I almost got broadsided by jacked-up pickup which ran a red light. Only averted that disaster because I look both directions before pulling out after a light changes.

A few days later I was coming back from grocery shopping after sunset, and about a mile from home, something didn't look right in the headlights. Got on the brakes and managed to stop before plowing into one of the neighbor's black bulls, which was standing in the middle of the road!

I get the feeling this car is a magnet for accidents. Good thing it has air bags.

Another actual reason that my engine swap has slowed is that another neighbor has offered to sell me her husband's 2005 Ford Ranger 4x4. He has Alzheimer's, and can no longer drive, so she's talking about making me a very attractive deal on it. Problem is, a rat built a big nest on top of the engine and chewed some important wires and hoses off to get room for nest expansion.

Took a couple of sessions with tweezers and hot dog tongs to remove the mass of the nest, then some time to sort of what kind of damage was going to need to be repaired before I tried to start the engine. Before I could make a start on repairs, her husband's condition deteriorated quickly, and he began being violent, refused to take his medications, etc.

This truck could be a bridge between getting my truck back on the road with the replacement engine, or it might be of better use as a replacement for my truck. At 39,000 miles, it's nearly new. Seat cover were fitted directly after buying it, so the interior is like new. Exterior is straight, with a few paint scratches, likely from their dog jumping up on the doors.

Well, great, solutions present themselves. BUT. The old man is a real handful, and I've been asked to put my interest and any repairs on hold until he can be safely relocated to a residential memory care facility. I've suggested that I could have it towed the half mile down the road to my place where I could work on it without causing any additional stress for her, but she won't have it. I think she is used to being in control, and her husband is out of control, so this is a way to have some jurisdiction over the situation.

So, I wait, keeping an eye open for any other attractive vehicles, and hoping that Lextanic doesn't cross paths with a road iceberg.